Optical measuring equipment business

AB Networks signed an exclusive distribution agreement in 2015 with NXT GmbH, a German spectrometer specialist, and has been importing core parts and assembling them in-house to supply major Korean companies and SMEs.

Advanced optical equipment requires highly skilled expertise because installation and maintenance are complex. AB Networks contributes to customers’ production and quality management by ensuring reliable measurement results through measurement-head installation and maintenance in high-vacuum chambers, as well as optical modeling.

Organic coating thickness measurement for OLED

Production of organic light-emitting diodes (OLEDs) is based on thin-film coating processes for various materials, such as indium tin oxide (ITO) or organic layers, with thicknesses ranging from 3 nm to 500 nm.

AB Networks provides a product lineup that can measure all types of layers used in current OLED stacks, including organic and inorganic layers, both inline and offline.

During deposition, various process parameters affect the thickness of the organic film and the optical constants n and k. Based on our experience in thin-film thickness measurement, specially designed optical components measure spectral reflectance and transmittance required for thickness and optical constant (n and k) measurement, ensuring measurement reliability, speed, and precision.

Web coating thickness measurement

(Secondary battery insulation film coating thickness measurement)

A thickness measurement system that considers both reflectance and transmittance can measure not only thin films in the ranges of 5 nm to 3,000 nm and 1 µm to 25 µm, but also thicker films from 0.5 µm to 1,300 µm.

High-speed inline measurement that also takes transmittance into account is available on the production line. It supports inline measurement and line scanning at production speeds such as 400 m/min and 800 m/min.

Glass Coating

Web Coating

Roll to Roll

Wet · Dry Coating

Vacuum Coating

Coating thickness measurement for electronic components such as PCBs

To measure solder resist coating thickness on PCBs and conformal coating thickness on various electronic components, thickness measurement at specific points may be required, such as on GND areas between patterns.

NXT’s TCM-microscope supports various measurement spot size options, including 5, 12.5, 25, 50, and 125 µm, enabling coating thickness measurement at specific points.

Pharmaceuticals and medical devices

Anti-reflection and hard-coating measurement for ophthalmic lenses

Non-destructive sampling enables process control and quality management. The only way to achieve quality targets and improve productivity is to apply comprehensive non-destructive inspection.

NXT provides non-contact instruments that can quickly and accurately measure the spectral reflectance and color appearance of anti-reflection (AR) coatings, as well as the thickness of hard-coating and varnish coating layers on transparent and translucent curved surfaces.

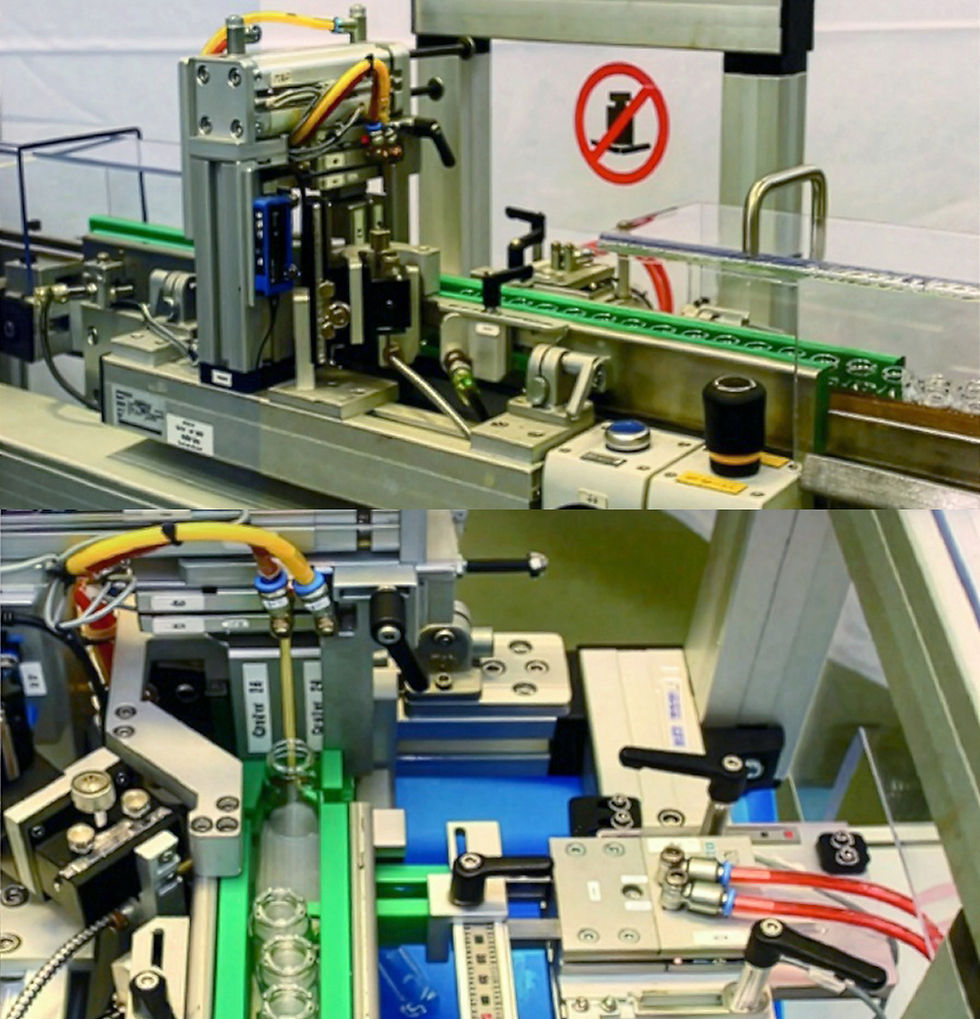

Vial inner coating thickness measurement

To verify the inner coating of vials and meet GMP quality requirements in pharmaceutical manufacturing processes, 100% inspection of vial coating thickness is essential.

-

100% inspection

-

Measures the thickness of more than 35 vials per minute

-

Easily adaptable to existing production lines in a modular format

Solar cells

Helios solar cell solution

Several process steps are required to produce solar cells. The most critical steps include texturing the bare wafer to reduce reflectance, doping to create the pn junction, and applying a SiN coating to provide an anti-reflection effect as well as increase passivation on the wafer surface. All of these process steps have a significant impact on cell efficiency.

Therefore, NXT provides a range of inline and offline measurement systems for process and quality control to ensure the stability and uniformity of process parameters across multiple process steps. By using NXT measurement systems, the highest cell performance can be ensured with the best cell efficiency.

Measurement principle

The Helios product line uses our well-known spectrometer and camera technologies. These technologies have been proven over 20 years across different industries. Optical configurations optimized for specific tasks are used to measure high-precision reflectance spectra and camera images.

Based on this data, NXT uses advanced mathematical algorithms and physical models to calculate layer thickness, refractive index, absolute reflectance values, and other parameters with very high accuracy and stability.

Our key customers